An Introduction To Troubleshooting 3D Printers

- Charles Edge

- Jun 23, 2022

- 13 min read

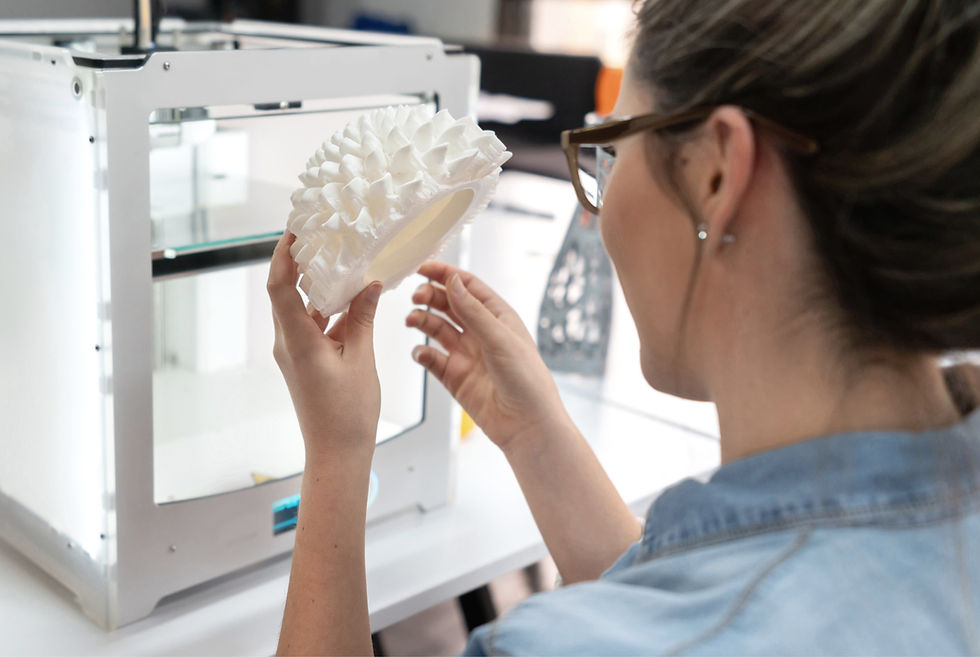

3D printing is one of the more rewarding hobbies for many in computing. We spend a lifetime telling computers to do things that remain virtual forever. This is our chance to produce objects in the real world from our labors. Yet it’s not as mature as many might expect, given that the standards we use today are old enough that their patents have long since expired. It’s still very much a hobbyist market.

There are two main standards for printers and in order not to be overly complicated we’re going to talk about FDM (Fused Deposit Modeling) printers in this article. FDM works by extruding (or pushing) long strands of plastic (which we call filament) through a motor, which we call a stepper, through a tube, and into a nozzle that’s headed up above 200 degrees Celsius, which may be referred to as a “hotend”. The nozzle is not very smart. It just knows to heat to the temperature the file instructs it to, and stay there until it gets a signal to change. The motor isn’t very smart either. It just knows to move at a given speed until it is told to stop.

The parts of the printer that are the smartest are the motors that move the extruder to where the filament needs to be to fuse to the layer below it. The printer receives instructors to move the extruder to various points on the X and Y axis while the motor pushes the filament out and thus lays down a layer of plastic on the bed of the printer (sometimes referred to as a build platform). Once a layer is done, the Z axis moves up and the next layer is drawn in plastic. The plastic is hot enough to fuse to the layer below as it’s being drawn.

There are a few elements of the print job that include the following:

Raft: Most printers support a horizontal mesh of filament that gets deposited on the bed of the platform. This is usually discarded once the job is complete.

Shell: This is the outer layers of the print that we see and are thicker and extruded more slowly than the parts on the inside.

Infill: The honeycomb or triangles that are inside the shell and provide structural integrity to the object being printed.

Supports: Gravity isn’t just a good idea, it’s the law. Any time the printer moves the nozzle and extrudes plastic at a given angle (usually 90 degrees but can be lower) where there isn’t anything below it, there’s nothing to fuse to. The laws of physics then pull the strand of filament down, so supports are there to hold the layer up and are then removed when the job is done (usually with snips, scissors, a knife, etc).

These are a lot of moving parts. The RepRap standard was designed to be that way to drive down the cost of printers. Each part uses inexpensive technology and so printers fell when the FDM patent expired and the RepRap standard was open sourced from thousands or tens of thousands of dollars, to hundreds (and sometimes even less than $100). Thus, there’s a bit more troubleshooting than many would like. The files we download or create (in ZBrush, Blender, etc) are stl files. Those contain dimensions in a rasterized format, and so we can increase and decrease the size of the object to print. We then use a tool called a “slicer” to convert that stl file into a gcode file that has specific instructions for our printer. This includes when and where to move the extruder, the temperature, when the motor that pushes the filament starts and stops, etc. Many printers come with their own slicer and many use a customized version of Cura. There are some 3rd party slicers like Simplify3D, Slic3r, SelfCAD, Repeater, Tinkering Suite, and others. YMMV with slicing software and I personally prefer to use Cura or whatever came with a given printer.

Now that we’ve looked at what these FDM printers are and how they print 3D objects, let’s look at the most common problems people will run into and some ways to fix them. Keep in mind that every printer is different and some may have different steps.

Nothing comes out. Re-calibrate (aka level). Also if there’s an option to calibrate the Z axis check that. Try changing the extrusion width in the slicer as well. Most filament is 1.75mm so check that that is correct.

Filament won’t stick to the bed. This is usually (although not always) an issue with the leveling of the printer. The first thing most printers instruct us to do when we unbox them is to level them. Some have “auto leveling” but that process might need to be run again. The standard way most people level a print bed is to put a sheet of paper between the bed and the nozzle and then turn nobs or push buttons according to the type of printer to lower the nozzle until it touches the paper. We want to lower the nozzle enough that we can feel it touch the paper but not so much that we can’t move the paper. You get the hang of it after a bit. If the nozzle is too close to the bed, no filament (or not enough) can come out. If the nozzle isn’t close enough to the bed then the filament for those first few layers can’t stick to the bed as the filament doesn’t actually touch it. This can also happen because the bed gets dirty. Some printers have glass beds and some have beds made of other materials. Consult the type you have first, but most are fine if cleaned with alcohol and an old toothbrush. I spray mine with hairspray when I clean it and can then turn off the raft for my prints. Another reason a print can not stick is that the bed is too hot. Try resetting print settings back to factory defaults in the slicer.

Parts of the print just kinda’ sag. Add supports or reduce the height of the layers in the slicer software.

The first few layers stick to the bed but then the print job collapses into a mess of hard plastic. This usually happens due to leveling.

The printer just makes a big mess in the same spot. This usually happens because a motor that moves an axis has a wire with a bad connection. Try unplugging and replugging each of the wires that control each axis again and according to the brand check that one of those motors isn’t burned out (it can happen). Can also happen due to leveling.

The print job worked but it’s hard to remove it from the raft. This can happen for a few reasons. One is again, leveling. Another is temperature. Check the packaging for the filament to make sure that the slicer sent the right temperature for the filament being used. Keep in mind that different brands or contents of filament can mean they need to burn hotter or cooler. For example, it’s not uncommon for filament with metal or wood to need to be hotter than filament that’s just PLA, PETG, or others without that additive.

The print job worked but is darker than it should be. This is almost always that the filament is being burned, and seems common with wood additives.

Layers leave more pronounced striations than they should be. There are a few reasons this can happen. The most likely is that the filament has enough moisture to not melt properly, or when it melts the moisture causes it to leave space between the layer below it as the moisture evaporates away. Filament can get too humid to burn properly. Always keep filament sealed and consider purchasing a dehumidifier. Try a fresh roll of filament and see if the issue persists. If so, lower the temperature of the print or slow down the speed of the prints.

Layers aren’t thick enough or the infill is exposed. This can be that the slicer doesn’t produce a thick enough shell or that the filament is old or burned too hot. Try resetting the settings for the printer in the slicer and reprinting. This could also mean the stl file isn’t fully enclosed. Blender especially can export files that can’t print properly. Anything downloaded from a site like Thangs or Thingiverse shouldn’t suffer from this but it happens. An option would be to open the file in a slicer like Cura then export it into the slicer for your brand of printer.

The print is too fragile. Either increase the shell or the percentage of infill. Most printers default to 10-20 percent infill but while it takes longer to print as this goes up, it produces a more solid object.

The print looks right mostly but it’s a bit of a mess and parts are hard plastic that sticks together where they shouldn’t be. This is often that we have too thick of shells or too much infill. It could also be that the filament is too hot, that we need to relevel the printer, or that the filament sucks. Yes, some filament sucks. Finally, once the above causes to this symptom have been ruled out, it could be a nozzle that’s gotten dull. These run hot and like all metal can get dull over time. They need to be replaced less often than they are, though, so keep the one taken out around in case that’s not the cause of the problem.

The motor for the stepper is knocking. This is usually that the printer is trying to print too quickly or isn’t hot enough for the filament being used. It can also happen with filament that has additives as the additives can actually come out while the filament is being fed through the stepper. Blow out the stepper, slow down the print speed in the slicer and try again.

The motor was knocking but now has a loud grinding sound. It actually sounds like the whole house is shaking. It’s funny how such a little motor can make so much sound. Then again, so can babies and they’re pretty small. If filament gets stuck in the reservoir of the nozzle and dried it can take some work to get it out. I usually pull the tube out, try to pull it out from one side but sometimes the filament breaks. If the motor can’t do it then we use pliers. If it still breaks and there’s none left in the nozzle then another option is to put the tube back in, feed it in and then use hands to push it through. Just be careful not to use the motor at the same time so it doesn’t get burned out. Also if pushing through, keep in mind that it can spurt out. Don’t get burned.

Some layers fall and don’t stick. This usually means it needs supports. Back to the gravity problem that humanity has struggled with since the first cave person dropped a rock on their foot.

The nozzle burned my finger. Don’t touch it, it’s hot.

The screen says something weird. Reboot, check that there’s an updated firmware, make sure the firmware is correct for the model of printer, and/or factory reset in that order.

The prints fail when sending over wifi. Reboot the printer and make sure it isn’t on a given screen. Some printers aren’t smart enough to accept a file when they’re on certain screens. If it still fails when sending, try it with USB. Most printers support both wifi and USB. The memory on them isn’t that great so if it can’t load it into the heap it can fail to submit. If it works over USB and not wifi and nothing at all works over wifi then check that the slicer has the right strings to submit. For example, some printers require custom codes be entered into a slicer like Cura - the way old modems used to have special codes for dial tones. If you’re typing in rando codes from some deep reddit thread then life can be rough but that’s part of a hobbyist device.

The printer ran out of filament and din’t finish the job. Load more. Seriously though, some printers come with a run-out detection or a pause function. I’ll only buy printers with the ability to pause. Run out detection is hit or miss.

The printer didn’t switch filament colors like I told it to. That’s a whole other article and you’re likely more advanced than this article and mocking what I type in here.

There are little strings or hairs that go between points on my print. The nozzle/extruder might be moving too slowly. It could also be that the retraction setting in the slicer needs to change or that the filament has a little moisture on it. Seems fairly common with metallic filament so triple check that the settings in the slicer are right for the filament. Also, I've literally seen hair in there. Move it away from pets if that's a thing.

Printer doesn’t power on. Recheck all cables, make sure it’s plugged in, and if plugged in make sure the outlet has high voltage power (and for example, isn’t on a light switch that’s off).

The buttons on the screen are too small and I can't press them. Get a stylus (preferably a quality rechargeable one that can be used with a tablet to draw cool stuff in Blender or whatever you design in once you get past the "print all the things on Thingiverse" stage).

Top layer pillows: The layers are likely cooling too quickly. Change that setting in the slicer. This is usually specific to different filaments so try a different filament and if it stops then that’s definitely a cooling setting.

First layer sticks out and looks squished. This is usually leveling again, but also check the first layer setting in the slicer and make sure it isn’t too low.

The printer makes me curse more than I’d like. There is no resolution for this issue. Could try and update the firmware in your brain but I hear that doesn’t work out all that well.

The infill falls before the shell is printed. Lower the speed of the infill print and try a different pattern.

Raft falls apart. Raft isn’t thick enough. I usually don’t mind as they just get recycled anyways.

Warping (the print kinda’ shifts as the layers go up or there's a drastic shift at one layer where the whole thing looks like it moved). Could be leveling or the print could not be adhering to the bed. Clean bed, try glue sticks or hairspray, and check the environment of the printer. If it’s an enclosed printer that’s probably not an issue. I prefer enclosed printers these days.

Some layers or parts of the shell are too thin. Usually leveling issues.

Layers aren’t sticking during a print. Check the cooling and leveling. Disable cooling if needed and reduce speed if that doesn’t work. One point, if you disable cooling and it doesn’t fix it, then reduce speed and that does fix it, turn cooling back on and see if it stays fix or if there are two different causes to a given symptom. Symptoms with two causes suck.

The supports are really hard to remove or break the print when removing. This can be a little tricky. Remove the raft before removing supports so there's room for the snips to push so it doesn't put too much pressure on little parts. Try to increase the air gap in the slicer or decrease the support percentage. If the layer falls put that back up and increase the pattern spacing setting in the slicer. Some slicers make automatic supports better than others. Some offer lines or weird vine-looking things. Try alternating between them. Really detailed prints are going to have hard supports to remove. I keep a thing of the gorilla glue with the brush on it by my desk.

There are weird little blobs on the print. Clean out the nozzle. Try a filament without additives or alternative between one with additives and one without every other print.

Filament gets tangled on the spool a lot. Some filament sucks. I’ve had a couple of rolls where the way they’re coiled at the factory, they just don’t come out right. I usually try a different roll, maybe roll out some extra slack and monitor it for a bit.

The printer is really loud. Clean it, level it, grease up anything that needs to be greased up, but honestly some printers are just really loud.

Can’t connect to the IP. Ping it, check the wireless setup, make sure the computer is on the right wireless network, update firmware, reset.

The USB stopped being recognized. Blow it out with some canned air, check for any schmutz in there (yup, that’s a technical term), unplug the wire to it and plug it back in.

Printer intermittently turns off. Put the cat up for adoption. True story (not the adoption part). The cats seem to really enjoy walking on top of the power strip, so I taped the button to the on position with electrical tape. Cats also enjoy attempting to attack slack filament. Also keep a vacuum around if you have pets. My dogs fur is embedded into some of my prints. Border Collies have two coats so when they shed the one during the spring it gets everywhere. All this gets back to what I said earlier about preferring enclosed printers. Pets…

Finally, sometimes you come home and there’s just a wild mess of crap that’s been spewing all over the place. Maybe that’s due to a missing support that got tangled and the whole thing just kinda’ spun out of control and now looks like a plastic plate of spaghetti. Don’t fret. Pull it all out, vacuum up the little bits, clean off the bed, check the levels and supports, and try again. It’s quite the rewarding hobby. Especially when you start painting. My friend Chip turned me on to Zenithal for shading. I’ll have to do another post on how to prime and Zenithal without losing all the detail on miniatures. I need to get good at it first, though. Wait, I didn’t get good at troubleshooting printers before I wrote about that so why wait!

OK, so at the beginning of the article I mentioned that there are two main standards. The second can get really, really detailed prints by dropping a build plate into vats of liquid resin over and over as the Z axis moves up. There are less parts, less things to go wrong, but it’s stinky and I’m pretty sure I’ll grow a third eye at some point from the chemical exposure even though I wear a mask when working with the resin. That works a lot like when you go to the dentist and they cure a filling with a UV light. The liquid resin gets exposed on the build plate with images per layer. Then when it raises up, the excess drips off, and the miniature comes out wet and stinky. That has an entirely different set of troubleshooting steps that mostly has to do with light, steps to dry, and what to do about impurities. But this is long enough and it’s time to move on for the evening.

Finally, there is a lot of room for innovation in the 3D printer space. There's room for new ideas, better hardware, more logic to help prevent some of the aspects that fail from failing, and so much more. This is still for hobbyists, the way the Altair, Apple I, and TRS-80 were computers made by hobbyists for hobbyists. The Macintosh of 3D printers hasn't been built yet, but when it does the hobby will likely turn into a trillion dollar market. For more thoughts on that, see our previous article on printing at https://www.bootstrappers.mn/post/it-s-time-for-3d-printing-to-evolve-from-the-hobbyist-market.

Comments